All subsidiaries of

Optimal Operational Area

Where Liquid Color can demonstrate its full Strenght and makes your Life easier!

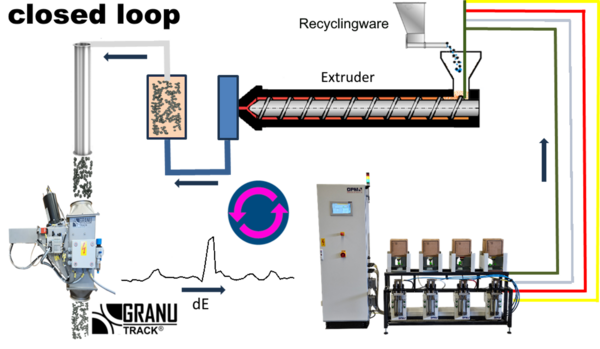

Recyclate Coloring

- NEW: The CLOOPMIX® system from OPM for inline coloring of recycled materials

- Precise liquid color dosing

- Intelligent recipe management

- Real-time color control with GranuTrack®

- Automatic adjustment by intelligent control algorithm in the event of color deviations

- Consistent color quality despite material fluctuations, with color deviations of less than ΔE 1

- ⇒ Product video

- ⇒ Brochure

Extrusion

- Films ⇒ no flowmarks and specks

- Compounds ⇒ efficient self coloring

- Profiles and fibers ⇒ Reduction of coloring costs

- Color injection downstream ⇒ time and material savings during color changes

- Examples: ABS edge bandings, engineering compounds, PP films, PVC flooring, PP fibers, HD-PE plates, filaments for 3D prints, PVC window profiles and many more

Injection Molding

- Thick-walled parts ⇒ possible saving on coloring costs, homogeneous colorization

- Thin-walled transparent parts ⇒ lower dosage, no specks, no flowmarks

- Hot runners ⇒ faster color changes (30 - 50 % less purging cycles)

- Engineering plastics (TPU, PBT, PA, ABS and the like) ⇒ lower raw material costs

- Commodities (PE, PP, PS) ⇒ reduced quantity of colorant

- Examples: PP pen tubes, TPU shoe soles, PE and PP caps, PC and ABS container, PS cutlery and many more

Mixing with liquid precursors

- LSR ⇒ Silicone oil as carrier, with approval for food contact if desired

- PVC ⇒ Softener can be used as carrier for liquid colors, thus 100 % compatibility

- Reactive resins and foams ⇒ liquid colors can be pre-mixed in one of the components

- Examples: Silicone components, PVC flooring, acrylic plates, window profiles, exercise balls, integral foam, flexible foam, PU shoe soles, adhesives, sealings, boat fender, buoys and many more